AWL and Teconnex Ltd collaboration for corrosion conditioning band clamps

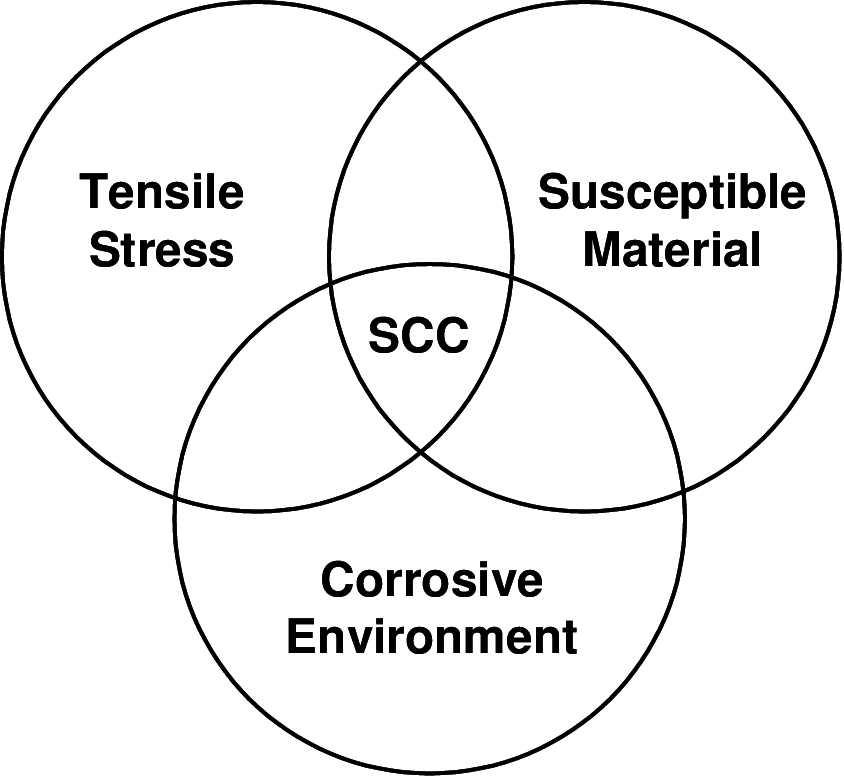

We are pleased to be working with Teconnex Ltd for corrosion conditioning to confirm the quality of their stainless-steel band clamps in terms of stress-corrosion cracking (SCC) resistance at critical areas such as welds and nut/bolt assembly arrangements.

Although high quality stainless steels like 304 and 316 are excellent material choices for any fabrication where corrosion may be a concern, poor welding control parameters in terms of heat input may compromise corrosion resistance locally at those areas.

Too much heat applied to a spot or weld bead using high grade stainless steels may ensure good penetration but can also provide a risk of chromium carbide migration to the grain boundaries causing lower corrosion and strength properties at those areas. Risk of SCC also can occur by the same mechanism if too much heat is generated during stainless steel bolt machining at the bolt head radius and at the ‘V’ troughs of the threads.

When stress and corrosion are combined within any assembly, the risk for failure from low cycle SCC by fatigue is greatly increased. This failure mode is more common when welding 304 grade stainless steels as the carbon/chromium ratio content is higher than 316 or 316L grade alloys.

After half a century of dedication to designing and manufacturing stainless steel clamps, Teconnex are global leaders in all clamp design and manufacturing projects and have demonstrated due diligence here by suppling samples for corrosion conditioning in a pre-stressed condition prior to strength testing by a third party as a part of their routine quality control.