From our Calne laboratories in Wiltshire, UK, we offer a comprehensive range of testing procedures and are committed to providing a competitive yet high quality UKAS accredited service not only to establish data, but to assist in research and development programmes where required.

AWL are pleased to be exporting our services to overseas companies in France, Spain, Germany, Italy, Turkey and the Far East.

AWL can provide our clients with the confidence they need to make informed materials performance decisions.

UV Weathering

UV weathering can cause damage to many coatings, plastics, fabrics and other materials. It can cause discolouration, fading, brittleness, cracking, peeling, reduce tensile strength and other mechanical properties.

Due to all the variables associated with real time weathering direct correlation is not possible as UV energy absorption levels and weather patterns, that influence ranges of temperature, humidity, wind and rainfall are changing year on year around the globe within temperate, tropical and arid regions. It is our view that accelerated weathering correlation statements should be taken with extreme caution and are best used as guidance for test duration and costing advice.

However, we can provide guidance here and have the capability to perform a wide range of accelerated weathering test methods to help establish a performance standard to provide our clients with greater confidence their product will withstand the elements within acceptable limits for its designed service life.

Corrosion

Our corrosion testing facilities include cyclic corrosion, neutral and acidified salt spray chambers to establish or validate the performance of a vast range of materials and barrier coatings on metals and polymeric materials.

For filiform corrosion resistance climatic chambers are used in conjunction with salt spray chambers. Filiform corrosion is often seen in stone chipped or kerb damaged alloy wheels and has the appearance of ‘worm like’ trails under the paint system. To measure the performance against filiform corrosion the test cycle must include a stable medium to high relative humidity set point otherwise the corrosion reaction will not form filiform trails.

The ISO 12944-6 standard alongside ISO 12944-9 (formally ISO 20340) are in constant demand at AWL Ltd. These standards are intended to assist adopting best practice in corrosion protection of structural steel at new constructions to extend costly maintenance periods. ISO 12944 is progressively superseding other standards to become a global benchmark in corrosion control and paint system performance.

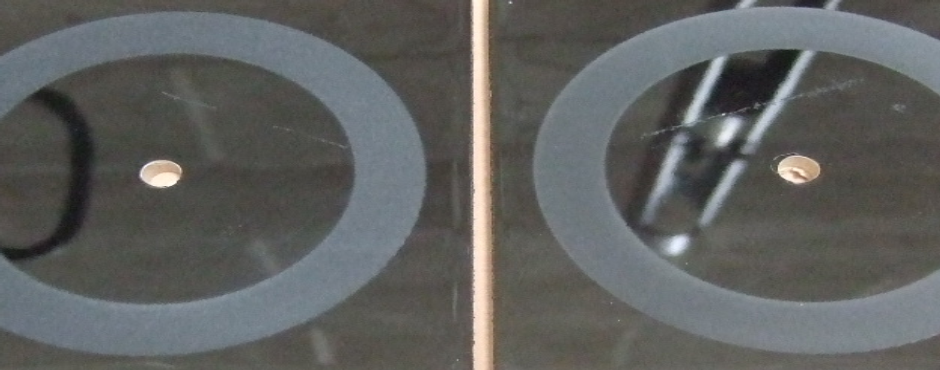

Number Plate Tests

Our number plate testing is based around the new British Standard BS AU 145e:2018 which has additional requirements for ANPR (Automatic Number Plate Recognition) including abrasion and contrast ratio between the character and the reflective.

Clauses of the standard include photometric, colorimetric and retro-reflection properties. UV aging from sunlight and weathering. Resistance to bending, impact, abrasion and salt spray. Thermal resistance to determine longitudinal distortion, reflective sheeting shrinkage, blistering, discolouration and delamination during extremes of temperature between +65 and -40 degrees centigrade. All clauses must be completed with satisfactory results to quality for a certificate of conformance which shall include full technical report traceability and commercial traceability where sub-contractor test housed are used.