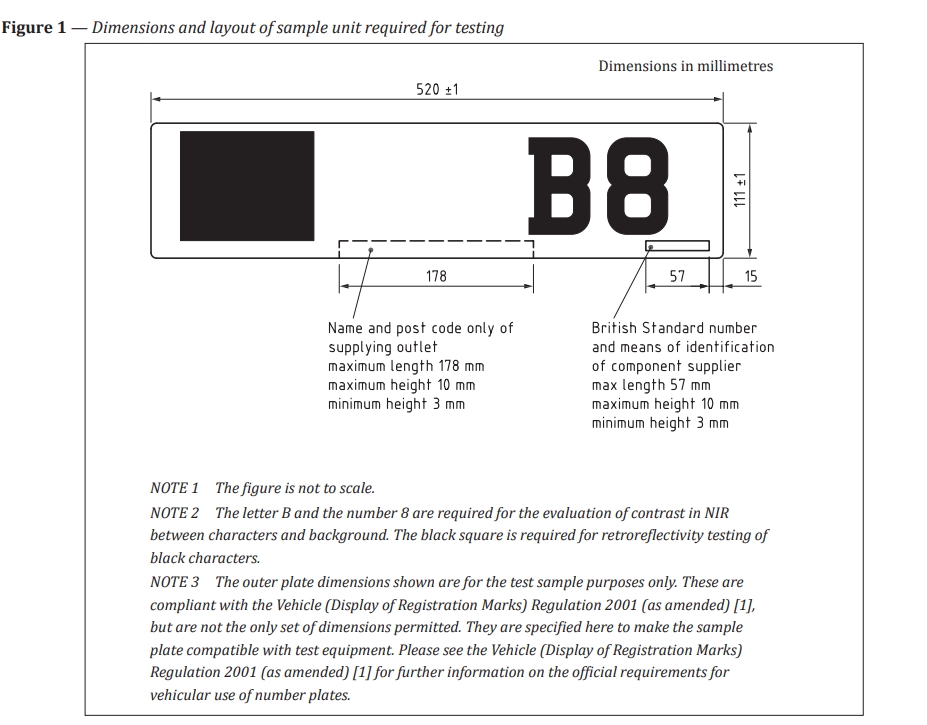

For impact and abrasion resistance testing of raised digits, a new sample lay-out will be trialled at AWL for the first time. The current issue of 145e falls short of approved test methodology for number plates with raised digits particularly for impact, abrasion and post-abrasion retests to confirm continued compliance to clauses 5.3, 7 and 8.

AWL welcomes positive contributions by any interested party including BS technical committee members and BNMA for practical and meaningful test methodology for impact and abrasion as well as foreseen modifications regarding the current thermal resistance test method in terms of additional assessment for adhesion at the centre of the plate where longitudinal distortion dynamics caused by thermal gradients between +65C and -40C shall provide the greatest challenge for adhesion of raised digits. It is hoped this additional discussion and R&D at AWL will help format the next issue of BSAU145.

Consideration to the return of the old 145d vibration rig for post-thermal, post-corrosion and post-weathering clauses may help provide a meaningful assessment for acceptance of adhesion alongside peel tests perhaps?

Post-weathering test results are also of concern since they may show colour shift with risk of ANPR contrast, retroreflection and colorimetric non-conformances.

There are some out there that may consider this approach too maverick for a test house and that we should remain neutral and should wait for the technical committees and other organisations/associations to do their stuff to introduce practical yet meaningful amendments to this British Standard to cater for the popularity of 4D and gel number plates.

I do not take this approach due to the glacial speed these organisation take to get things done.

Lets face it. The demand is high and 4Ds are here to stay!

To be continued……..