AWL are pleased to be helping a number of clients with clause 4.1.6.4 of BS EN ISO 12402-7:2020. This clause requires accelerated weathering conditioning to an energy absorption at the sample surface of 500kJ/m2 using daylight filtered xenon arc exposures.

Typical samples are life nets, life jacket fabrics, zippers, marine webbing, stitching threads, ropes and associated polymeric loops and brackets. The exposure profile is multi-cyclic consisting of light and dark periods with controlled humidity and long segments of water spraying and drying in the light and dark phases.

BS EN ISO 12402-7:2020 stipulates the detailed safety requirements for life-saving personal flotation systems and devices. It covers a wide range of materials and components ensuring that each element of the flotation device is scrutinised for safety, durability and effectiveness with low risk of failure.

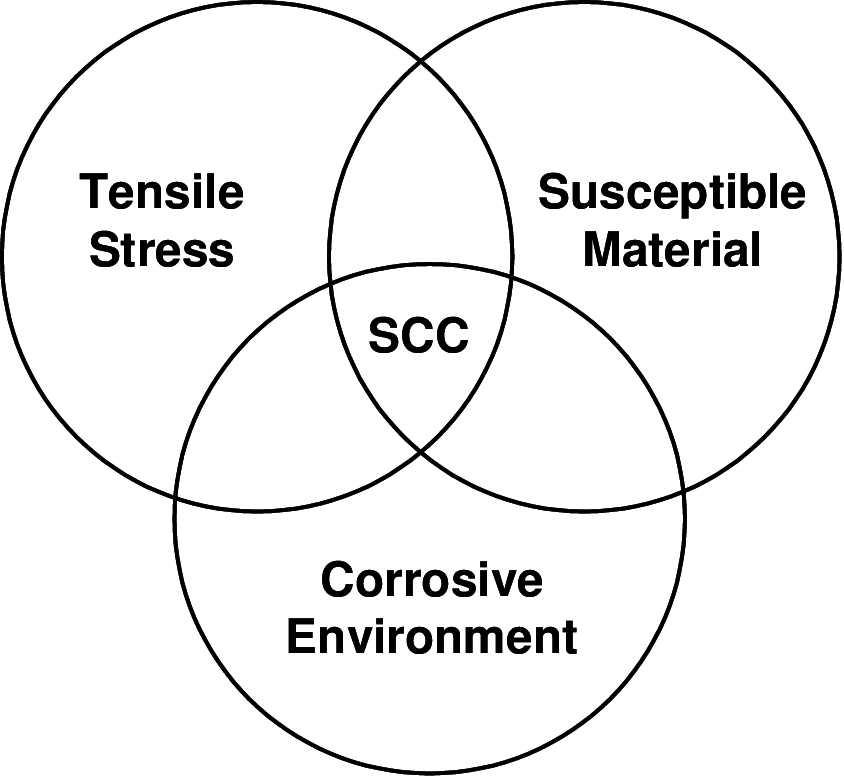

The standard is often chosen in conjunction with BS EN ISO 9227 where exposures to salt laden atmospheres may be required to confirm corrosion durability to ensure safety. Typical examples are suspected low-grade stainless-steel loops, brackets and fixings (nuts, bolts, washers’ screws etc..).

Material conformance to both of these standards are used by due-diligent manufacturers and regulatory bodies who are committed to maintaining the highest standards for water safety equipment both on and offshore.