Gel and 3D number plate digits

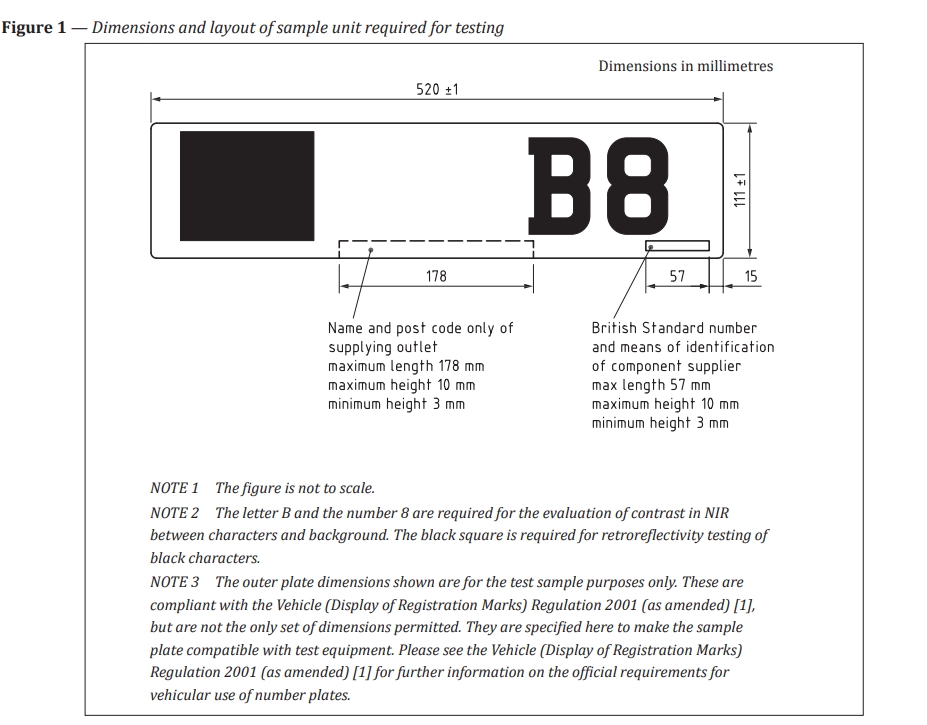

We would like to remind any potential manufacturers of gel and 3D number plate digits, that the sample units submitted for testing shall be prepared according to Fig 1 of BS AU 145e:2018 (see below) onto fully constructed number plates using acrylics, adhesives and reflective sheets that have previously demonstrated conformance to 145e.

A sticky point with raised digits of any kind is the requirement for abrasion resistance that is currently required over the reflective only. There is concern here at AWL that when raised digits are abraded according to 145e, they may change colour/contrast causing them to fail post-abrasion colour, contrast and retro-reflection requirements.

We have seen black gel and acrylic 3D digits turn a grey after abrasion (clause 13) and UV weathering testing (clause 15).

AWL would suggest a specific sample unit for abrasion testing (if we are to stay with the current 145e methodology) that comprises of the characters B and 8 shown in Fig 1 but mounted centrally and longitudinally using the correct spacing ensuring the minimum length is 200mm to suit the stroke length requirements of clause 13. Discussions are ongoing………….watch this space.